Accuracy forms the backbone of reliable measurements, yet many professionals overlook a critical process that ensures their instruments deliver trustworthy results. Kalibraatio, the systematic comparison of measurement devices against known standards, represents far more than routine maintenance.

This comprehensive guide explores everything you need to know about kalibraatio, from fundamental concepts to advanced implementation strategies. Whether you’re working in manufacturing, healthcare, research, or quality control, understanding proper calibration techniques can dramatically improve your measurement reliability and operational efficiency.

By the end of this post, you’ll have a clear roadmap for implementing effective kalibraatio procedures that enhance accuracy, ensure compliance, and ultimately save time and resources in your daily operations.

Understanding Different Types of Kalibraatio

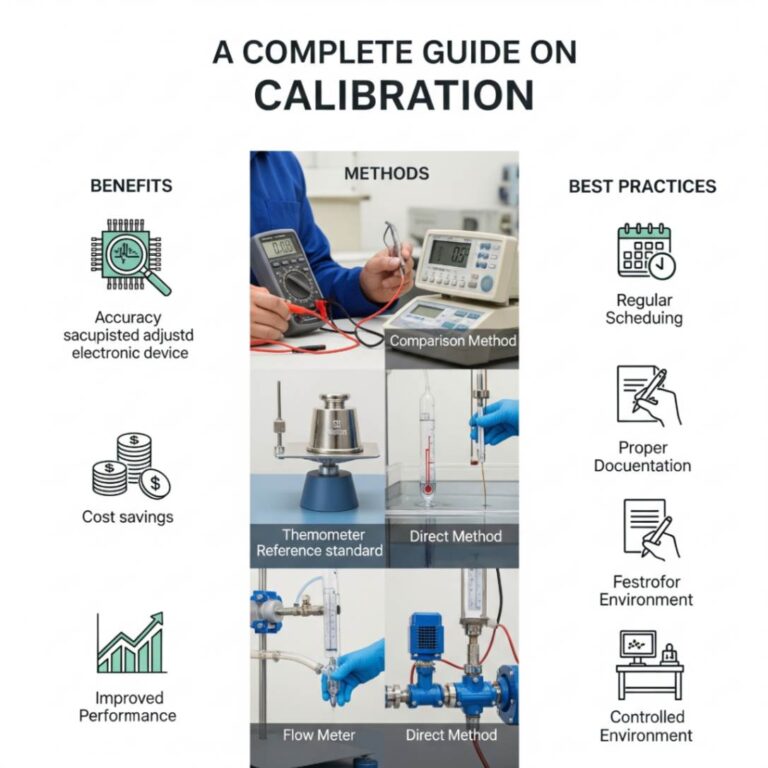

Kalibraatio encompasses several distinct approaches, each suited to specific instruments and accuracy requirements. Recognizing these variations helps you select the most appropriate method for your needs.

Internal Kalibraatio

Internal kalibraatio uses built-in reference standards within the measuring instrument itself. Many modern digital devices incorporate this feature, allowing operators to verify basic functionality without external equipment. While convenient, internal kalibraatio typically provides lower accuracy levels compared to external methods.

External Kalibraatio

External calibration involves comparing your instrument against separate, traceable reference standards. This method delivers higher accuracy and forms the foundation of most professional calibration programs. External procedures typically require specialized equipment and trained technicians.

Comparative Kalibraatio

Comparative kalibraatio measures your instrument against another device of known accuracy. This approach works well when reference standards aren’t readily available, though it requires careful selection of the comparison instrument to ensure meaningful results.

Key Benefits of Regular Kalibraatio

Implementing consistent kalibraatio practices delivers measurable advantages across multiple operational areas. These benefits extend beyond simple accuracy improvements to encompass broader business objectives.

Enhanced Measurement Reliability

Regular calibration ensures your instruments maintain specified accuracy levels throughout their operational life. This reliability becomes crucial when making critical decisions based on measurement data, particularly in environments where small variations can have significant consequences.

Regulatory Compliance

Many industries mandate specific calibration requirements to maintain certifications and meet regulatory standards. Documented kalibraatio records provide essential evidence of compliance during audits and inspections.

Cost Reduction

While kalibraatio requires upfront investment, it prevents costly errors that result from inaccurate measurements. Early detection of instrument drift allows for timely corrections before problems escalate into expensive rework or quality failures.

Extended Equipment Life

Proper calibration procedures often reveal developing issues before they cause complete instrument failure. This early warning system enables proactive maintenance that extends equipment lifespan and reduces replacement costs.

Step-by-Step Kalibraatio Implementation

Successful kalibraatio requires systematic planning and execution. Follow this structured approach to establish reliable procedures that deliver consistent results.

Planning Phase

Begin by identifying all instruments requiring kalibraatio within your operation. Create a comprehensive inventory that includes instrument types, accuracy requirements, usage frequency, and criticality to your processes. This inventory forms the foundation for developing appropriate kalibraatio schedules.

Document the required accuracy levels for each instrument based on your specific applications. Consider both manufacturer specifications and your operational needs when establishing these requirements.

Preparation Steps

Gather necessary reference standards, ensuring they maintain traceability to national or international standards. Verify that reference equipment accuracy exceeds your instrument requirements by an appropriate margin, typically 4:1 or better.

Prepare the measurement environment by controlling temperature, humidity, and other factors that might influence results. Many calibration procedures specify environmental conditions that must be maintained throughout the process.

Execution Process

Record initial instrument readings before beginning kalibraatio adjustments. These baseline measurements help track instrument performance over time and identify developing trends.

Apply known input values using your reference standards, comparing instrument responses to expected results. Document any deviations and determine whether adjustments are necessary to bring the instrument within acceptable limits.

Make required adjustments following manufacturer procedures, then repeat measurements to verify that corrections achieved desired accuracy levels.

Documentation Requirements

Maintain detailed records of all calibration activities, including dates, procedures used, results obtained, and adjustments made. These records serve multiple purposes, from tracking instrument performance to demonstrating regulatory compliance.

Essential Best Practices for Optimal Results

Implementing proven best practices significantly improves kalibraatio effectiveness while reducing time and resource requirements.

Frequency Optimization

Establish kalibraatio intervals based on instrument stability, usage patterns, and accuracy requirements. Start with manufacturer recommendations, then adjust schedules based on your experience with instrument drift rates.

Critical instruments may require more frequent calibration, while stable devices in controlled environments might extend intervals without compromising accuracy.

Environmental Control

Minimize environmental variables that can affect kalibraatio results. Temperature fluctuations, vibrations, electromagnetic interference, and other factors can introduce errors that compromise accuracy.

Allow adequate stabilization time for both reference standards and test instruments before beginning procedures. This settling period ensures measurements reflect true instrument performance rather than temporary environmental effects.

Staff Training

Invest in comprehensive training for personnel performing calibration activities. Proper technique significantly impacts result quality and consistency across different operators and periods.

Regular refresher training helps maintain skill levels and introduces new techniques or equipment as they become available.

Real-World Case Studies

Understanding how kalibraatio delivers practical benefits helps justify implementation efforts and demonstrates return on investment.

Manufacturing Quality Control

A precision machining company implemented comprehensive calibration for its measuring equipment and reduced scrap rates by 35% within six months. Regular calibration of calipers, micrometers, and coordinate measuring machines ensured consistent part quality while identifying worn tooling before it affected production.

The documented kalibraatio program also streamlined customer audits and supported ISO 9001 certification renewal without complications.

Laboratory Operations

A materials testing laboratory discovered significant measurement drift in their universal testing machine through routine calibration. Early detection allowed corrective action that prevented invalidation of customer test results and maintained laboratory accreditation.

The incident highlighted the importance of frequent calibration for high-use equipment and led to revised maintenance schedules that prevented similar issues.

Healthcare Applications

A hospital’s biomedical engineering department reduced equipment downtime by 40% after implementing proactive calibration schedules for patient monitoring devices. Regular kalibraatio identified failing components before they caused complete device failure, allowing repairs during scheduled maintenance windows rather than emergencies.

Making Kalibraatio Work for Your Operation

Successful kalibraatio implementation requires commitment to systematic procedures and continuous improvement. Start by assessing your current practices and identifying areas where enhanced accuracy would deliver the greatest benefits.

Develop a comprehensive kalibraatio program tailored to your specific instruments and operational requirements. Consider partnering with qualified service providers for complex equipment while building internal capabilities for routine procedures.

Remember that kalibraatio represents an investment in measurement quality that pays dividends through improved accuracy, reduced errors, and enhanced operational efficiency. Take the first step by inventorying your measurement equipment and establishing baseline accuracy requirements for your critical processes.