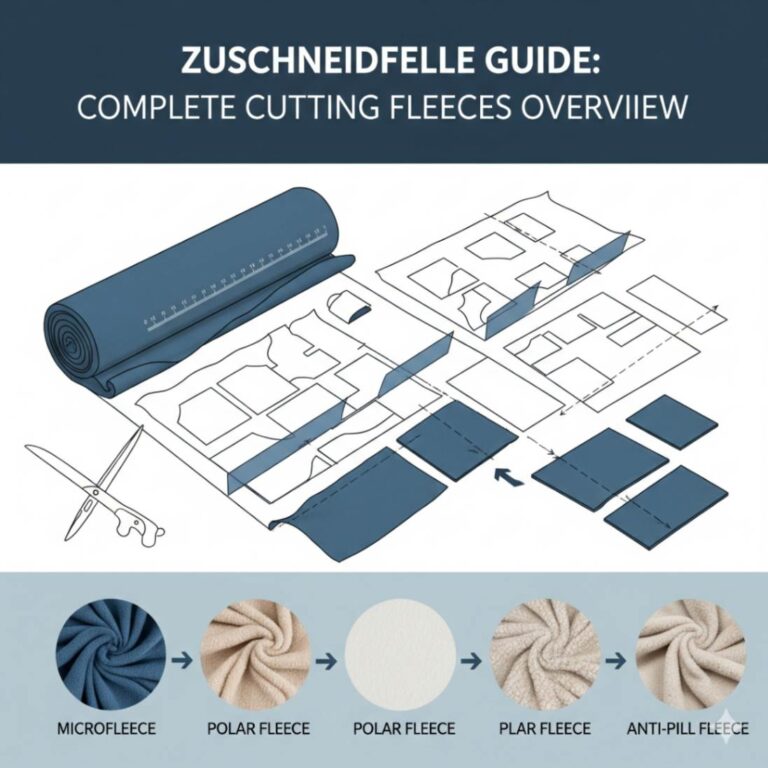

When working with sheepskin and leather crafts, having the right materials makes all the difference. Zuschneidfelle represent a specialized category of cutting fleeces that have become increasingly popular among craftspeople, furniture makers, and textile enthusiasts. These carefully prepared materials offer unique properties that make them ideal for various applications, from upholstery projects to artistic endeavors.

The growing interest in sustainable materials and traditional craftsmanship has brought renewed attention to these versatile fleeces. Whether you’re a seasoned professional or just starting your journey into leather and fleece work, understanding what makes zuschneidfelle special will help you make informed decisions for your projects.

What Are Zuschneidfelle?

Zuschneidfelle are specially prepared cutting fleeces that come from sheep and other animals, explicitly processed for crafting and manufacturing purposes. The German term literally translates to “cutting fleeces,” which perfectly describes their primary function in various industries. These materials undergo specific preparation processes that make them ideal for cutting, shaping, and working into finished products.

Unlike regular fleeces or raw hides, zuschneidfelle are treated to achieve optimal flexibility, durability, and workability. This preparation involves careful cleaning, tanning, and conditioning processes that preserve the natural qualities of the material while making it suitable for precision work. The result is a product that combines the natural beauty and warmth of sheepskin with the practical benefits needed for professional applications.

The quality of these cutting fleeces depends heavily on the source material, processing methods, and intended use. High-grade zuschneidfelle maintain their natural softness while providing the structural integrity needed for demanding applications. This balance makes them particularly valuable for artisans who require materials that are both beautiful and functional.

Historical Background and Origins

The use of cutting fleeces dates back centuries, rooted in traditional European craftsmanship where artisans valued every part of the animal. Historical records show that Germanic tribes and later medieval artisans developed sophisticated methods for preparing and utilizing these materials. The techniques for creating what we now call zuschneidfelle evolved from these ancient practices.

During the Middle Ages, guilds of leatherworkers and furriers refined these preparation methods, establishing standards that influence modern production techniques. The term “zuschneidfelle” itself reflects this Germanic heritage, combining practical functionality with linguistic precision that characterizes German craftsmanship terminology.

The industrial revolution brought mechanization to fleece processing, but traditional hand-preparation methods remained important for high-quality applications. Modern zuschneidfelle production combines these time-tested techniques with contemporary quality control methods, ensuring consistent results while maintaining the character that makes these materials special.

Types and Classifications

Natural Zuschneidfelle

Natural cutting fleeces represent the traditional category, featuring materials processed with minimal chemical intervention. These fleeces retain their original texture, color variations, and natural properties that craftspeople have valued for generations. The preparation focuses on cleaning and basic preservation while maintaining the material’s inherent characteristics.

Natural zuschneidfelle typically display the authentic colors and markings of the source animal, creating unique patterns that add character to finished products. This category appeals to artisans who prioritize authenticity and natural beauty in their work. The processing methods emphasize gentle techniques that preserve the fleece’s natural oils and flexibility.

Quality variations within natural cutting fleeces depend on factors like animal breed, age, and environmental conditions. Premium natural zuschneidfelle come from carefully selected sources and undergo meticulous preparation processes that enhance their best qualities while addressing any imperfections.

Processed and Treated Varieties

Processed cutting fleeces undergo additional treatments to achieve specific properties or appearances. These treatments might include dyeing, texture modification, or chemical processing to enhance durability or workability. The goal is to create materials that meet specific requirements while maintaining the essential qualities that make zuschneidfelle valuable.

Color-treated varieties offer consistent coloration and can match specific design requirements. These processed options expand the creative possibilities for craftspeople while providing predictable results. The treatment processes are designed to integrate seamlessly with the natural material structure, avoiding the stiffness or artificial feel that characterizes inferior products.

Modern processing techniques also include treatments for specific applications, such as flame-retardant preparations for upholstery use or antimicrobial treatments for medical applications. These specialized varieties demonstrate the versatility of zuschneidfelle and their adaptability to contemporary needs.

Key Properties and Characteristics

Physical Properties

The physical characteristics of cutting fleeces make them uniquely suitable for various applications. Zuschneidfelle typically exhibit excellent tensile strength, allowing them to withstand cutting, stretching, and shaping without tearing or losing integrity. This strength comes from the natural fiber structure, which remains intact through proper processing.

Flexibility represents another crucial property, enabling craftspeople to work the material into complex shapes and forms. Quality cutting fleeces maintain their flexibility even after processing, allowing for intricate work that would be impossible with stiffer materials. This characteristic proves particularly valuable in upholstery and artistic applications where the material must conform to curved or irregular surfaces.

The natural insulation properties of these fleeces provide thermal regulation benefits in finished products. This characteristic makes them popular for items like seat covers, clothing elements, and decorative pieces, where temperature control enhances comfort and functionality.

Aesthetic Qualities

Visual appeal plays a significant role in the popularity of zuschneidfelle among craftspeople and consumers. The natural texture variations create visual interest that synthetic materials cannot replicate. Each piece displays unique characteristics that contribute to the individuality of finished products.

Color variations within natural cutting fleeces range from pure white to deep browns and grays, with many pieces showing beautiful gradations and patterns. These natural colorations provide a palette that complements various design styles, from rustic and traditional to contemporary and minimalist approaches.

The surface texture of quality zuschneidfelle offers both visual and tactile appeal. The soft, plush feel invites touch while the natural luster catches light in ways that enhance the material’s beauty. These qualities explain why these materials command premium prices in markets where aesthetics matter as much as functionality.

Manufacturing Process

Source Selection

The quality of finished zuschneidfelle begins with careful source selection. Premium producers choose materials from animals raised in optimal conditions, ensuring that the fleeces have the density, strength, and appearance characteristics needed for high-quality cutting fleeces. This selection process considers factors like animal breed, age, health, and environmental conditions.

Regional variations in source materials contribute to different characteristics in the finished products. European sources, particularly those from mountainous regions, often produce fleeces with superior density and durability. Understanding these regional differences helps buyers select materials that match their specific needs and quality requirements.

The timing of material collection also affects quality, with seasonal variations influencing fleece characteristics. Experienced processors work with suppliers who understand these factors and can provide consistent quality throughout the year.

Processing Stages

The transformation from raw fleece to finished zuschneidfelle involves multiple carefully controlled stages. Initial cleaning removes impurities while preserving the natural oils that contribute to the material’s workability. This stage requires expertise to achieve thorough cleaning without damaging the delicate fiber structure.

Tanning processes stabilize the material and prepare it for long-term use. Traditional tanning methods often produce superior results for cutting fleeces, though modern techniques can achieve similar quality with greater consistency. The choice of tanning method affects the final characteristics of the material, including flexibility, durability, and appearance.

Quality control throughout processing ensures that each batch meets established standards. This includes testing for strength, flexibility, appearance consistency, and other critical characteristics. Reputable manufacturers maintain detailed records of their processes and conduct regular quality assessments to ensure consistent results.

Applications and Uses

Traditional Crafts and Artistry

Zuschneidfelle have long been prized in traditional crafts where authenticity and natural beauty are paramount. Leatherworking artisans use these materials for projects ranging from decorative items to functional goods. The workability of cutting fleeces allows for detailed carving, tooling, and shaping that creates stunning finished products.

Folk art traditions in many cultures incorporate these materials into traditional costumes, ceremonial items, and decorative objects. The natural variations in color and texture complement conventional design elements while providing durability that allows these items to be passed down through generations.

Modern artisans continue to explore creative applications for zuschneidfelle, incorporating them into contemporary sculptures, wall hangings, and mixed-media artworks. The natural properties of these materials offer unique possibilities for artistic expression while connecting modern work with traditional craftsmanship techniques.

Commercial and Industrial Applications

The commercial applications for cutting fleeces span numerous industries where natural materials provide advantages over synthetic alternatives. Furniture manufacturers use zuschneidfelle for high-end upholstery projects where authenticity and luxury appeal to discerning customers. The natural properties of these materials contribute to comfort and durability in seating applications.

Automotive applications include seat covers, steering wheel wraps, and interior trim elements, where the natural texture and temperature regulation properties enhance the driving experience. Premium vehicle manufacturers particularly value the unique character that cutting fleeces brings to interior design.

Fashion and accessories represent another significant market for these materials. Designers incorporate zuschneidfelle into handbags, shoes, clothing elements, and accessories where the natural beauty and unique characteristics justify premium pricing.

Comparison Table: Types of Zuschneidfelle

Type | Processing Level | Natural Color | Durability | Price Range | Best Applications |

|---|---|---|---|---|---|

Natural | Minimal | Yes | High | $$$ | Traditional crafts, art |

Semi-processed | Moderate | Partially | Very High | $$ | Furniture, upholstery |

Fully Treated | Extensive | No | Excellent | $ | Commercial, industrial |

Premium Natural | Minimal+ | Yes | Superior | $$$$ | Luxury goods, collectibles |

Specialty Treated | Targeted | Variable | High | $$$ | Specific applications |

Quality Assessment and Selection

Visual Inspection Criteria

Evaluating Zuschneidfelle quality requires attention to several visual characteristics that indicate proper processing and source quality. Uniform thickness across the surface suggests consistent processing and high-quality source material. Variations in thickness can create weak spots that affect the material’s performance in demanding applications.

Color consistency within acceptable natural variations indicates proper processing techniques. While natural color variations are desirable, extreme inconsistencies or unnatural appearances may suggest processing problems or inferior source materials. Quality cutting fleeces display natural beauty without obvious flaws or processing artifacts.

Surface texture should feel soft and supple without being overly oily or dry. The natural oils should be balanced to provide workability without creating a greasy feel. Quality materials maintain their texture consistency across the entire surface, without rough or damaged areas that could affect the finished product’s appearance.

Testing Methods

Physical testing helps verify the quality claims made by suppliers and ensures that materials meet project requirements. Tensile strength testing determines how much stress the material can withstand before failure, which is crucial for applications involving cutting, stretching, or heavy use.

Flexibility testing assesses how well the material maintains its properties when bent, folded, or shaped. Quality zuschneidfelle should return to their original form after moderate stress without showing permanent deformation or damage. This characteristic proves essential for applications requiring complex shaping or repeated handling.

Aging tests expose materials to accelerated conditions that simulate long-term use. These tests reveal potential problems with color stability, texture changes, or structural degradation that might not be apparent in new materials. Reputable suppliers provide aging test results that demonstrate their products’ long-term performance characteristics.

Key Takeaways

Understanding zuschneidfelle requires appreciating their unique combination of natural beauty, practical functionality, and traditional craftsmanship heritage. These cutting fleeces offer properties that synthetic materials cannot replicate, making them valuable for applications where authenticity and performance matter equally.

Quality assessment involves multiple factors, including visual inspection, physical testing, and understanding the processing methods used. The investment in premium zuschneidfelle often proves worthwhile for projects where material quality directly affects finished product value and longevity.

Proper selection requires matching material characteristics with intended applications while considering factors like budget constraints and availability. Working with reputable suppliers who understand these materials ensures access to consistent quality and expert guidance for specific applications.

The versatility of cutting fleeces continues to create new opportunities as craftspeople and manufacturers discover innovative applications. From traditional crafts to contemporary design, these materials bridge the gap between historical authenticity and modern functionality.

According to industry experts at newsasshop.co.uk Blog, the growing interest in sustainable and natural materials has increased demand for quality zuschneidfelle across various industries. This trend suggests continued growth in both traditional and innovative applications for these versatile materials.

Conclusion

Zuschneidfelle represent a unique intersection of traditional craftsmanship, natural materials, and practical functionality that continues to find new applications in our modern world. Whether you’re pursuing traditional crafts, contemporary design projects, or commercial applications, understanding these materials’ characteristics and capabilities will help you make informed decisions that enhance your finished products.

The investment in quality cutting fleeces pays dividends through superior workability, durability, and aesthetic appeal that synthetic alternatives cannot match. As interest in authentic materials and sustainable practices continues to grow, zuschneidfelle will likely maintain their importance in various industries where natural beauty and functional excellence remain valued qualities.

Taking time to understand source quality, processing methods, and application requirements ensures that your projects benefit from all the advantages these remarkable materials offer. With proper selection and handling, cutting fleeces can transform ordinary projects into extraordinary results that showcase the enduring appeal of natural materials and traditional craftsmanship techniques.